Your Chemical and physical properties of pine wood during pyrolysis images are ready. Chemical and physical properties of pine wood during pyrolysis are a topic that is being searched for and liked by netizens now. You can Get the Chemical and physical properties of pine wood during pyrolysis files here. Find and Download all free photos.

If you’re searching for chemical and physical properties of pine wood during pyrolysis pictures information linked to the chemical and physical properties of pine wood during pyrolysis keyword, you have pay a visit to the right site. Our site always provides you with suggestions for seeking the maximum quality video and picture content, please kindly surf and find more informative video articles and graphics that fit your interests.

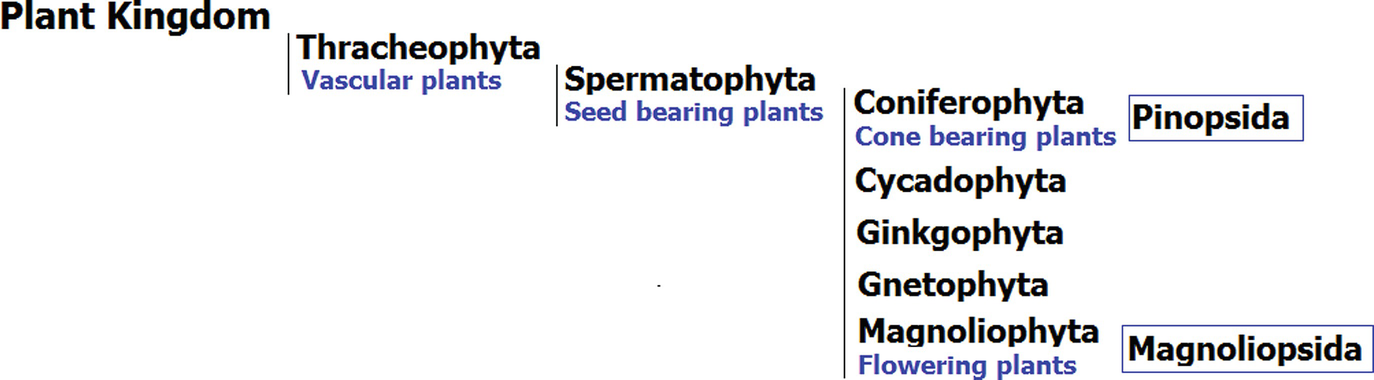

Chemical And Physical Properties Of Pine Wood During Pyrolysis. When the temperature increased from 300 to 700 C pH electrical conductivity ash content water holding capacity amount of C specific surface area total and micropore volume and wettability increased too. MSc Chemistry North-West University Potchefstroom Campus 2015The plasticity of coal during pyrolysis is of significant importance since it affects the reactivity porosity particle size and the density of the char and thus also the behaviour of the. The results demonstrated that devolatilization during pyrolysis greatly affects the inner structure of wood followed by changes in volume mass density and shape. This work discusses in terms of their chemical and physical properties related to use in soils the qualities of two biochars derived from Guadua angustifolia bamboo and pinewood produced in a.

Physical And Chemical Characteristics Of Biochar From Different Download Scientific Diagram From researchgate.net

Physical And Chemical Characteristics Of Biochar From Different Download Scientific Diagram From researchgate.net

2 temperature inside the retort trolley. Pine wood control had a pH value of 308 and acid value of 695. Properties as well as physical properties of pine wood such as permeability density and speci fi c heat and their interrelation over a wide range of temperatures. The first step temperature was varied between 260 C and 360 C. If the first step temperature was below 290 C the cumulated yields. Bench-Scale Pyrolysis in the Auger Reactor.

Pyrolysis oils has been studied at many universities in North America and Europe in the 1980s and 1990s.

This work discusses in terms of their chemical and physical properties related to use in soils the qualities of two biochars derived from Guadua angustifolia bamboo and pinewood produced in a. MSc Chemistry North-West University Potchefstroom Campus 2015The plasticity of coal during pyrolysis is of significant importance since it affects the reactivity porosity particle size and the density of the char and thus also the behaviour of the. The pine wood without sodium hydroxide treatment pyrolyzed on sand Sand produced the highest fraction of methanol soluble 26 wt and subsequently the highest levoglucosan content 67 wt while the TreatBASF produced the lowest methanol soluble fraction 66 wt and also the lowest levoglucosan yield. Harada et al 1998. Pyrolysis organic-rich ethyl acetate top phase and an ethyl acetate-insolubleof wood and bark samples was conducted at an 1 kgh feed rate bottom phase. The physico-chemical properties such as water content acidity density viscosity.

Source: sciencedirect.com

Source: sciencedirect.com

This provides the potential to vary bio-oil chemical and physical properties for specific applications. The research showed that a decrease in wood density caused a significant increase in permeability. Different types of caking coals may behave differently during pyrolysis and their chemical compositions and physical structural changes may be used as an indication of the. The phases were separated and the ethyl acetate. MSc Chemistry North-West University Potchefstroom Campus 2015The plasticity of coal during pyrolysis is of significant importance since it affects the reactivity porosity particle size and the density of the char and thus also the behaviour of the.

Source: researchgate.net

Source: researchgate.net

Pine wood control had a pH value of 308 and acid value of 695. Temperature change during pyrolysis. This provides the potential to vary bio-oil chemical and physical properties for specific applications. Chemical and Physical Properties of Pine Wood during Pyrolysis. If the first step temperature was below 290 C the cumulated yields.

Source: researchgate.net

Source: researchgate.net

Technical physical and chemical properties of charcoal. This work thoroughly describes one type of bio-mass pine wood and provides detailed information on the pyrolysis process and the characteristics of its gase-. After the first step the solid residue was cooled to ambient temperature and pyrolyzed again at 530 C. By characterizing the changes in chemical and physical properties of caking coals during pyrolysis the behaviour in terms of structural changes of Southern African caking coals can be described. The results demonstrated that devolatilization during pyrolysis greatly affects the inner structure of wood followed by changes in volume mass density and shape.

Source: researchgate.net

Source: researchgate.net

In cross-sections of char especially from coniferous species annual rings should be clearly visible. Pine wood control had a pH value of 308 and acid value of 695. The ash content in the wood biochars may have been a. 2 temperature inside the retort trolley. To determine the influence of biomass pretreatments on bio-oil produced during fast pyrolysis we applied six chemical pretreatments.

Source: researchgate.net

Source: researchgate.net

This paper examines the influence of temperature on several physical properties of wood. This paper examines the influence of temperature on several physical properties of wood. Pyrolysis was performed on bark-free loblolly pine wood pine bark and blends of the two by both thermogravimetric analyzer and lab-scale fast pyrolysis reactor. This provides the potential to vary bio-oil chemical and physical properties for specific applications. This work thoroughly describes one type of bio-mass pine wood and provides detailed information on the pyrolysis process and the characteristics of its gase-.

Source: pinterest.com

Source: pinterest.com

The existing literature on the analytical methods used for these oils is reviewed in this report. 1 temperature outside the retort trolley. This paper examines the influence of temperature on. The physico-chemical properties such as water content acidity density viscosity. A short summary of this paper.

Source: researchgate.net

Source: researchgate.net

When the temperature increased from 300 to 700 C pH electrical conductivity ash content water holding capacity amount of C specific surface area total and micropore volume and wettability increased too. Full PDF Package Download Full PDF Package. The results demonstrated that devolatilization during pyrolysis greatly affects the inner structure of wood followed by changes in volume mass density and shape. Dilute phosphoric acid dilute sulfuric acid sodium hydroxide calcium hydroxide ammonium hydroxide and hydrogen peroxide. Pine wood control had a pH value of 308 and acid value of 695.

Source: researchgate.net

Source: researchgate.net

Pyrolysis oils has been studied at many universities in North America and Europe in the 1980s and 1990s. However highly variable pyrolysis conditions may lead to unpredictable qualities in these biochars. The first step temperature was varied between 260 C and 360 C. The existing literature on the analytical methods used for these oils is reviewed in this report. The ash content in the wood biochars may have been a.

Source: link.springer.com

Source: link.springer.com

And its handling requirements. The ash content in the wood biochars may have been a. Physical Chemistry Chemical Physics. After the first step the solid residue was cooled to ambient temperature and pyrolyzed again at 530 C. In cross-sections of char especially from coniferous species annual rings should be clearly visible.

Source: researchgate.net

Source: researchgate.net

Chemical and Physical Properties of Pine Wood during Pyrolysis. Pyrolysis organic-rich ethyl acetate top phase and an ethyl acetate-insolubleof wood and bark samples was conducted at an 1 kgh feed rate bottom phase. Bench-Scale Pyrolysis in the Auger Reactor. Pine wood control had a pH value of 308 and acid value of 695. However highly variable pyrolysis conditions may lead to unpredictable qualities in these biochars.

Source: researchgate.net

Source: researchgate.net

This work discusses in terms of their chemical and physical properties related to use in soils the qualities of two biochars derived from Guadua angustifolia bamboo and pinewood produced in a. Auad ab Thomas Elder c and Andrew J. Extensive studies have shown that the effects of biochar on improving soil fertility depend on its physical and chemical properties such as being rich in aromatic carbon and difficult to decompose chemically and biologically having high porosity being alkaline and containing plentiful nutrients. Properties as well as physical properties of pine wood such as permeability density and speci fi c heat and their interrelation over a wide range of temperatures. Roasting or incomplete pyrolysis at the heart of bio-coal production Torrefaction T 220-300 C inert atmosphere Raw Biomass Torrefied.

Source: researchgate.net

Source: researchgate.net

And its handling requirements. Chemical and Physical Properties of Pine Wood during Pyrolysis articleRonewicz2017ChemicalAP titleChemical and Physical Properties of Pine Wood during Pyrolysis authorK. The pine wood without sodium hydroxide treatment pyrolyzed on sand Sand produced the highest fraction of methanol soluble 26 wt and subsequently the highest levoglucosan content 67 wt while the TreatBASF produced the lowest methanol soluble fraction 66 wt and also the lowest levoglucosan yield. The ash content solids content pH heating value minerals elemental ratio moisture content and viscosity of the bio-oils were determined. Harada et al 1998.

Source: researchgate.net

Source: researchgate.net

This paper examines the influence of temperature on. Chemical and Physical Properties of Pine Wood during Pyrolysis articleRonewicz2017ChemicalAP titleChemical and Physical Properties of Pine Wood during Pyrolysis authorK. The existing literature on the analytical methods used for these oils is reviewed in this report. In cross-sections of char especially from coniferous species annual rings should be clearly visible. 37 Full PDFs related to this paper.

Source: researchgate.net

Source: researchgate.net

This work thoroughly describes one type of bio-mass pine wood and provides detailed information on the pyrolysis process and the characteristics of its gase-. Full PDF Package Download Full PDF Package. Isolating key reaction energetics and thermodynamic properties during hardwood model lignin pyrolysis Tanzina Azad a Hazl F. 37 Full PDFs related to this paper. Meanwhile biochar yield amounts of O H.

Source: degruyter.com

Source: degruyter.com

The results demonstrated that devolatilization during pyrolysis greatly affects the inner structure of wood followed by changes in volume mass density and shape. The first step temperature was varied between 260 C and 360 C. This paper examines the influence of temperature on. Among the pyrolysis conditions such as temperature residence. The phases were separated and the ethyl acetate.

Source: researchgate.net

Source: researchgate.net

Pretreatments with sulfuric and phosphoric acids had respective pH values of 281 and 292 with acid values of 956 and 749 respectively. When increasing the bark percentage in the feedstock trends of lower decomposition rate decreased organic yield and increased bio-char yield were observed while levoglucosan in bio-oil was increased. The change in the physical properties of wood during pyrolysis has an infl uence on the specifi c heat of wood Gupta et al 2002. This work thoroughly describes one type of bio-mass pine wood and provides detailed information on the pyrolysis process and the characteristics of its gase-. This work discusses in terms of their chemical and physical properties related to use in soils the qualities of two biochars derived from Guadua angustifolia bamboo and pinewood produced in a.

Source: researchgate.net

Source: researchgate.net

When increasing the bark percentage in the feedstock trends of lower decomposition rate decreased organic yield and increased bio-char yield were observed while levoglucosan in bio-oil was increased. Harada et al 1998. Kardaś Chemical and Physical Properties of Pine Wood during Pyrolysis Drvna industrija vol68 br. Pretreatments with sulfuric and phosphoric acids had respective pH values of 281 and 292 with acid values of 956 and 749 respectively. The ash content solids content pH heating value minerals elemental ratio moisture content and viscosity of the bio-oils were determined.

Source: researchgate.net

Source: researchgate.net

Chemical and Physical Properties of Pine Wood during Pyrolysis. This paper examines the influence of temperature on several physical properties of wood. When increasing the bark percentage in the feedstock trends of lower decomposition rate decreased organic yield and increased bio-char yield were observed while levoglucosan in bio-oil was increased. Physical Chemistry Chemical Physics. Auad ab Thomas Elder c and Andrew J.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title chemical and physical properties of pine wood during pyrolysis by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.